Topley Pike Mine

United Kingdom

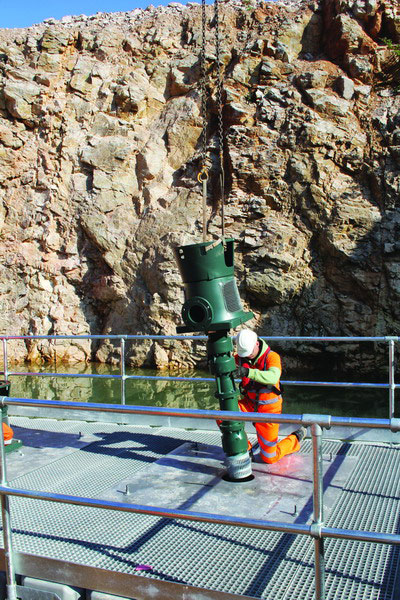

Quarry Dewatering

Prior situation

The plant needed to be modified due to problems relating to unplanned maintenance and failures. Moreover, there was a need to improve the general operational efficiency of the plant, the existing pumps of which were powered by a diesel generator. Sites had been experiencing high failure rates with expensive repair costs – plans to increase flow rate and remain operational throughout the year had been proposed. The size of the submersibles required a NPSH of 3-4 metres positive inlet pressure, which could only be achieved by lowering the pumps to a submerged position that drew rocks and heavy solids up from the bottom of the bed. By using the pumps above this level, cavitation was being experienced.

Caprari solution

A solution was required to reduce downtime/maintenance costs and expensive failures. When a conventional submersible motor fails, it is not always economically to repair the motor when compared to the cost of buying a new pump.

Rather than replacing the old pump for a new one, a policy to look at reducing overall LCC at the site was implemented, reducing obsolescence from scrap and improving efficiency to allow the plant to be more flexible.

Benefit obtained

With Caprari’s linehsaft pump, the motor can be easily maintained above water level. The pump was able to absorb less power at higher heads, reducing overall running costs and routine maintenance costs.

Related Projects

How can I help you?

Faq

Frequently asked questions and relevant responses all in one place

Services

Find the right solution for you through our pre-sale service

Want to know more about available products?

Our team is here to help.